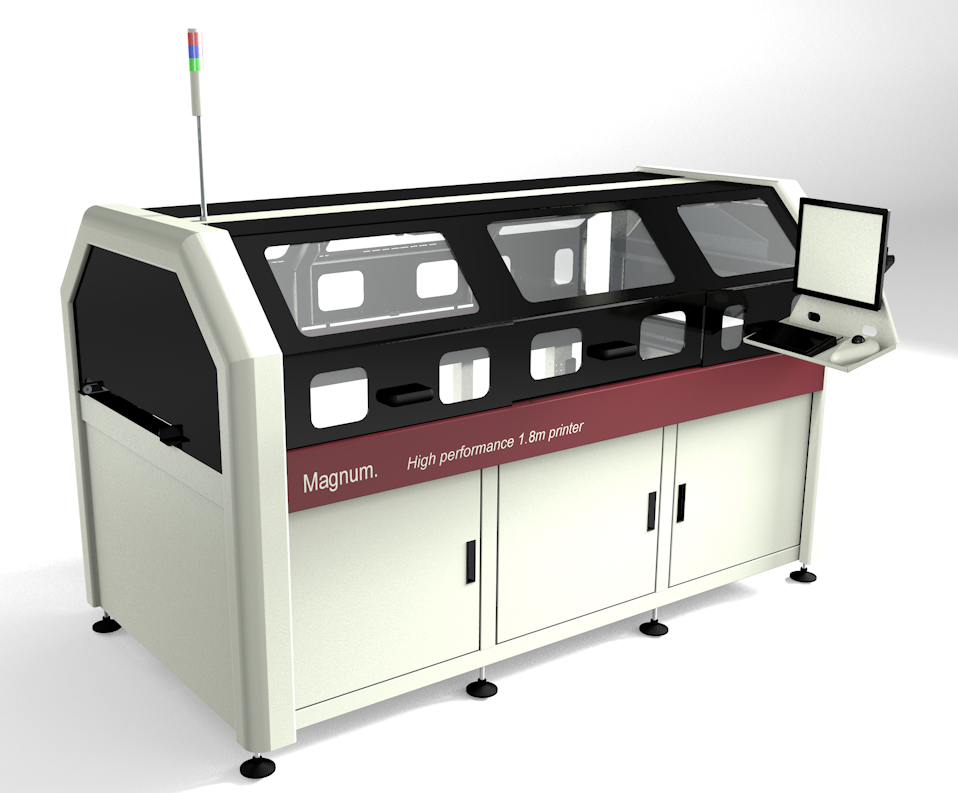

Fast product setup and change over

Maximum print area 1800mm x 600mm

Print speeds 5-250mm/S

Print pressure 0.1 to 20Kg

High accuracy vision alignment system

Simple ‘Point and Click’ Vision Set-up

Robust construction for precise, repeatable printing

Fast, precise closed loop servo motor control throughout

Auto conveyor and stencil width adjustment

Various tooling options available

Unlimited product file storage

Automatic stencil cleaner with wet/dry and vacuum operation

Easy, intuitive operator software

Heavy board handling as standard

Optional post-print 2d inspection

Optional automatic paste on stencil dispenser

SMEMA interface protocol

Low cost of ownership

English, German and French languages. Others on reques

Conveyor and stencil width settings for different board sizes are adjusted automatically making product changeover quick and simple. The intuitive user software makes operating the printer easy and includes a step by step setup procedure to ensure error-free product file generation.

Numerous tooling options are available ranging from manually placed tooling posts to automatic tooling options such as Vacu-nest and GridLok.

Printer options include a fully automatic under stencil cleaner with wet, dry and vacuum assist modes, an automatic paste on stencil dispenser system and a post print 2d inspection system that can simultaneously check both board and stencil for possible printing errors.

The conveyor system is designed for heavy board handling with fully programmable transport speeds and direction.

It is compatible with SMEMA and other interface protocols.The ability to print such a wide range of board sizes, its easy of use and low cost of ownership makes the Magnum printer the ideal partner for all your production needs